Description

►Brief introduction of this automatic block making machine Italy

QTF8-15 is a fully automatic concrete block making machine.

1. High degree of automation: adopts imported PLC program control system, which is easier to operate for users.

2. Advanced technology: all key electronic control components, motors and hydraulic and pneumatic components are made of well-known foreign products, such as YUKEN’s hydraulic control, to guarantee the high reliability of equipment operation.

3. Versatility functions: different cement blocks can be produced by changing different molds

4. Environmental protection: no waste residue, waste water and harmful gas are generated in the concrete blocks making process

5. More available raw materials: fly ash, waste construction waste, slag, cinder and so on all can be used as raw materials for this automatic paver block machine.

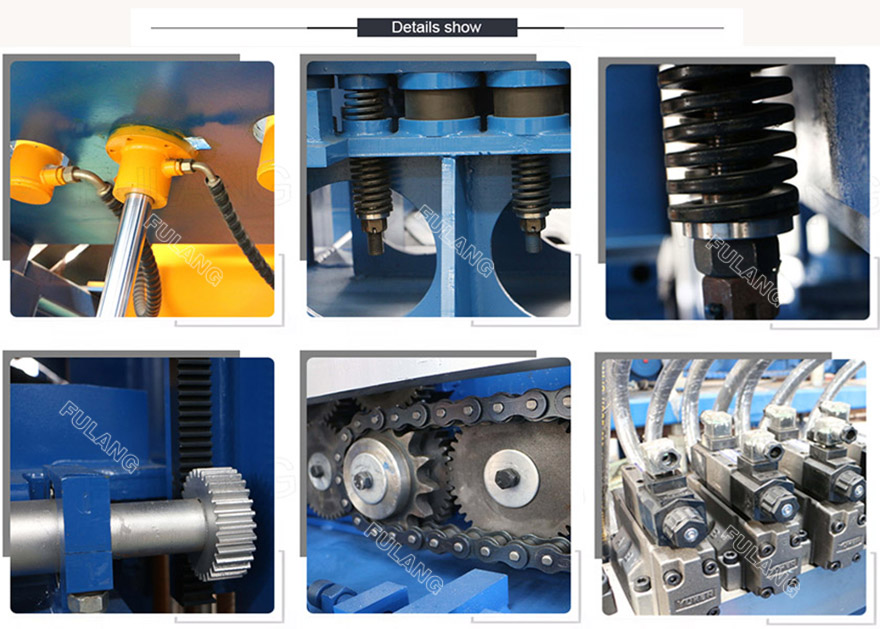

►Machine details show

►Technical parameters and theoretical production capacity

| Technical Parameters | |||

| Weight of host machine | 8.5T | Molding area | 936x880mm |

| Power of host machine | 29.1KW | Vibration force | 60-80KN |

| Water consumption | 5-10T/Day | Mixer model | JS750 |

| Pallet size | 980x900x25mm | Workshop | 260m2 |

|

Theoretical Production Capacity |

|||

| Size(LxWxH) | Pcs/Mould | Pcs/Hr | Pcs/8Hr |

| 400x100x200mm | 16 | 2880-3360 | 23040-26880 |

| 400x150x200mm | 10 | 1800-2100 | 14400-16800 |

| 400x200x200mm | 8 | 1440-1680 | 11520-13440 |

| 400x250x200mm | 6 | 1080-1260 | 8640-10080 |

| Solid:230x110x70mm | 33 | 5940-6930 | 47520-55440 |

| Paver:200x100x60xmm | 32 | 5760 | 46080 |

| Paver:200x100x60xmm | 20 | 3600 | 28800 |

► Different brick samples

The following is only part of bricks for your reference, if you have other special needs we can customize other brick for you.

► Installation abroad

► Certificate