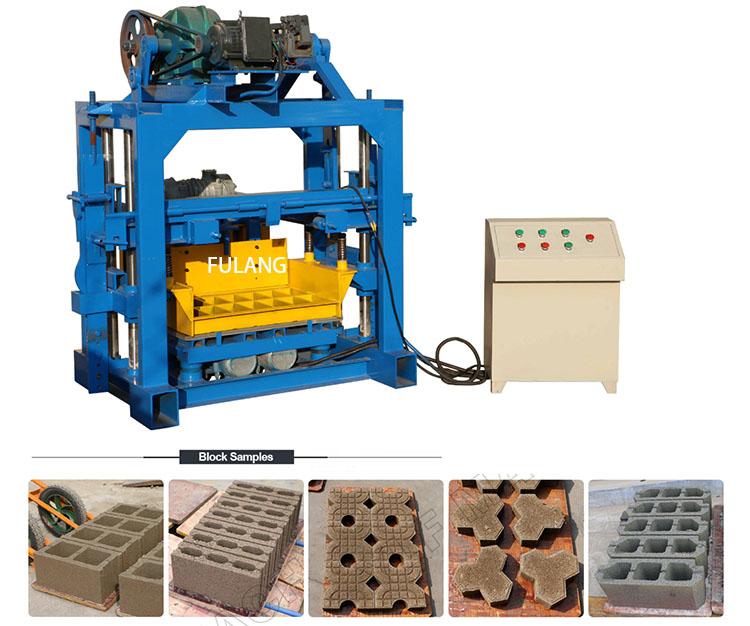

This QTF40-2 small concrete block making machine is easy to operate and can replace all kinds of mould to produce all kinds of fire-free bricks.

Performance Features:

For fixed (non-mobile), mode vibration, mechanical demoulding. It has been proved by the long-term use of users that its structure is reasonable and its working principle is reasonable, and it has the following prominent characteristics:

1. Optimized demoulding mode: the belt pulley and the chain sprocket are used for demoulding instead of reducer, so the structure is simple, strong and durable, convenient for maintenance, safe and reliable, without reducer leakage, and save power. The demoulding power is only 1.2kW.

2. In addition to the frame itself, the suspension and connection parts of the whole machine all use springs to increase the buffer force. In the process of vibration forming, the head, core, box and pallet can vibrate at the same time, which ensures the high compactness and uniformity of the brick produced. Moreover, the machine runs smoothly with little noise, thus achieving a good effect of vibration reduction.

3. The head can be moved longitudinally to facilitate feeding, washing and maintenance.

4. The mold USES the line cutting technology, the appearance dimension is accurate, therefore produces the brick the corner is regular. Moreover, it is easy to change. Through changing the mold, 115, 140, 240 and other sizes of standard bricks can be produced, as well as a variety of different specifications of blocks and curb stones, and various special-shaped molds can be customized according to the requirements of users. And the mold is the use of carburizing heat treatment and carefully made, the service life is generally more than 10 years.

5. The brick supporting plate is in synchronous resonance with the grinding tool and the mold frame when it is formed, so that the supporting plate has a longer life without impact force.

Because this brick machine has the above many characteristics, so the production of block size accurate, high strength, just produced above the brick can bear the weight of a person, so a short time can be stacked, save the production site area.

This block machine has less investment, ADAPTS to all kinds of raw materials as auxiliary materials, gives full play to the advantage of local materials, and is the best choice for individual and construction units to produce and apply on site.

Its main parameters:

1. Power: 4.8KW

2. Molding cycle: 35S

3. Examples of blocks per mold:

390X190X190(mm)(length X width X height) 4 pieces (single and double row holes)

390X150 (140) X190mm)(length X width X height) 5 pieces (through hole, Cardinal hole

390 X 240X190 (mm)(length X width X height) 3 blocks (single, double and three rows of holes)

240X115X53nm)(length X width X height) 21 blocks

390 X 115 X 190mm)(length X width X height) 6 pieces (through hole, blind hole)

4. Size of wooden pallet: length X width X thickness 900X450X25(mm)