Description

Technological superiority

- Intelligent operation

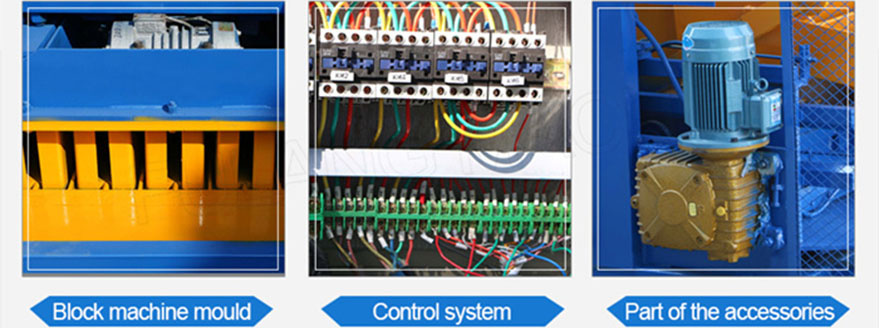

The hollow block molder equipment adopts international advanced intelligent interactive system, visual operation interface, including security logic control and fault diagnosis system.

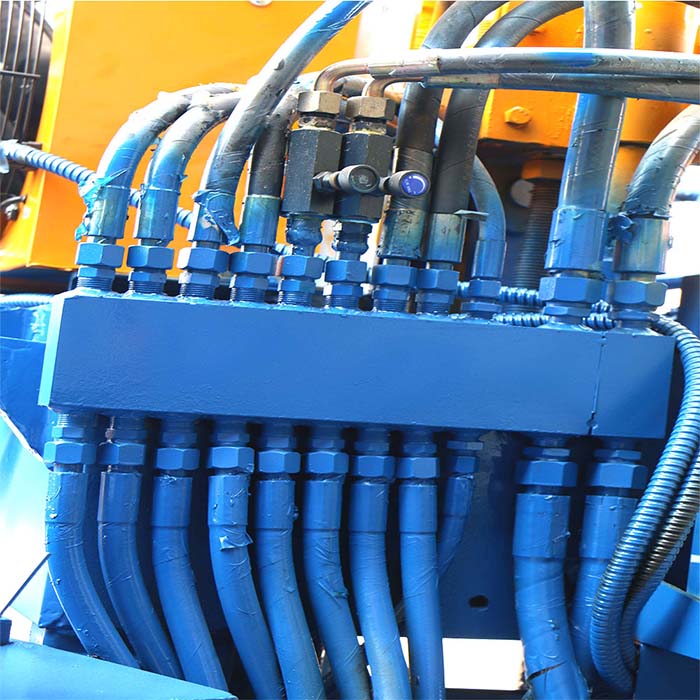

- Hydraulic system

The speed and pressure of hydraulic action are accurately controlled by proportional valves, and all parameters can be set at the operating interface. The main movements of the machine, such as the movement of the shaking table, the lifting of the mold frame and the press head, and the movement of the cloth frame, are driven by the hydraulic system.

- Mobile production

The egg laying concrete block machine equipment is equipped with high quality walking wheels, which can realize mobile production. No brackets are needed. Motor drive, stable and reliable.

- Precision movement of indenter

The press head of the equipment moves along the large-sized guide axis and guide column through the chain and lever axis, which is safe, stable and accurate.

- Multifunctional Distribution System

The system consists of hopper, guide rail, distribution box and lifting system. The unique mould scraper and the mould brush fixed on the cloth box can ensure the surface cleanliness of the brick and the uniformity of the cloth.

| Technical Parameters | |||

| Dimension | 3150X1800X2400mm | Weight of host machine | 7.8T |

| Demold method | Hydraulic pressure | Host machine power | 16kw |

| Voltage | Adapt to your local voltage | Vibration frequency | 50-70Hz |

| Shaping cycle | 10-15s | Mixer model | JS 500 |

Hollow, solid, block and paver samples

This machine can produce different kinds of blocks just by replacing molds. and the molds are customizable according to customer’s requirement.

Customer visiting