Well connected mechanical equipment is quality equipment, cement color brick making machine is the same. In the production process, if there is a slight deviation, we will not sell directly to customers. In addition to these aspects, cement brick machine in other aspects of the performance is relatively good, has attracted everyone’s attention and research.

Cement color matching machine in vibration and pressing should be strictly controlled. Summarize the best ratio between productivity and quality. If necessary, adjust the amount or frequency of feeding to achieve balance. Use defoaming agent, qualified hydraulic oil and other additives to clean the oil and filter of the brick-making machine. The brick making machine should be level. Twist bottom face above eccentric shaft, smooth grease filling point for once per shift.

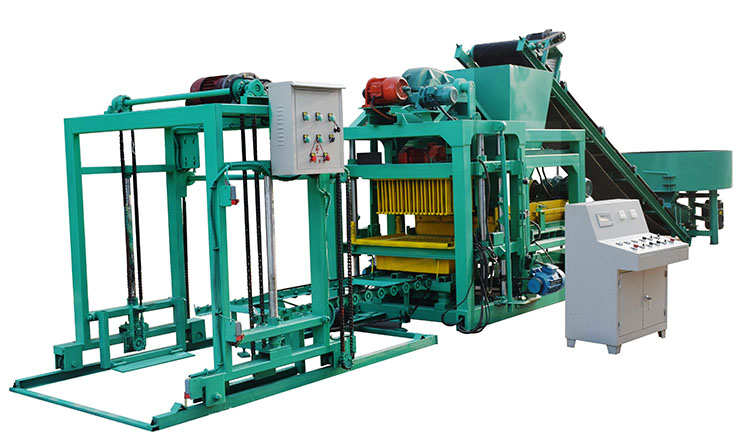

Color brick machine hydraulic vibration, lower upper pressure, stimulate vibration, forced double cylinder. The density and compressibility are so high that there is no honeycomb in the brick. Large gas station with built-in strong cooler. The rapid cooling of hydraulic oil extends the service life of hydraulic components and ensures the stability of production under high temperature environment. The trigger sent is the crank link push plate and brick. The newly formed block brick has high product rate and is not easy to be broken. The feeder is specialized for block machines. Different bricks arrive at different materials, adhere to the common strength, density and appearance of the brick, can improve work efficiency. Adjustable control electric control cabinet adopts the technology of active and manual electric panels into one cabinet.