Dimension of host machine 3700x2100x2300mm

Total machine power 29kw

Mould period 25s

Vibration force 35.5KN

Pallet size 850x550x20mm

Mixer model JQ500

Workshop area 160m2

Voltage Customized

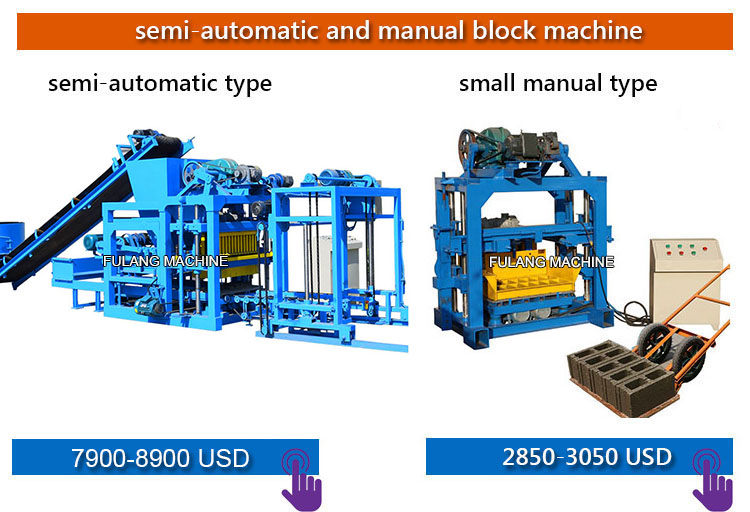

QTF4-25A/QTF4-25B:

The QTF4-25 fly ash brick making machine was developed on an old small machine. As our best-selling hollow block machine, it has some outstanding advantages.

The all-concrete block manufacturing frame is made of high-quality steel with a special welding process.

Difficult to weld and durable.

Advanced electronic control technology, reliable hydraulic system, simple operation and stable performance.

Four guide rails make the mold and head positioning more precise.

The advanced vibration technology and the arch-breaking device are used to realize the comprehensive vibration control of the material, and the feeding speed is fast and uniform.

Vertical vibration in the direction of the lower mold and pressure vibration of the upper mold greatly improve the production efficiency, so the bulk density is uniform and the strength is high.

——————————————————————————————————-

brick making machine tanzania,block making machine for tanzania,brick force wire machine,building block making machine,manual concrete block making machine,paving block making machine,brick making machine spare parts hs code,spare parts for interlocking brick machine,styrofoam block making machine,manual brick making machine in papua new guinea,plc controller block making machine,mini model hollow block machine vedeo,building block making machine,manual concrete block making machine,paving block making machine,block making machine made in maroc casablanca,brick making machine durban,building block making machine,makiga brick making machine,block brick making machine.