When we talk about brick making machine. We always be amazed by Chinese high technology which is adopted in the manufacturing and improvement of brick machine.

Both the concrete block making machine and interlocking brick making machine have amazing technology. The hydraulic molding system is an update of vibration molding system. It not only have higher molding pressure, but also have more uniform pressure. So the brick produced have higher strength and density. And the surface of block is smoother. The hydraulic molding system has higher energy efficiency than the vibration molding system. So the upgrade technology have more energy saving.

The second factor we need to mentioned is the advanced line cutting technology. About the line cutting technology, many people maybe not very familiar with it. In fact, it’s a precise cutting technology. Compared with the traditional cutting technology, the line cutting technology has more precise cutting size. The size can be controlled within 0.02mm. So the block mould made by this method has more precise size to confirm the size of brick. In addition, the block mould also adopt the carburizing heat treatment. So the mold has longer service time. Normally, our block mould can be used more than 15 years.

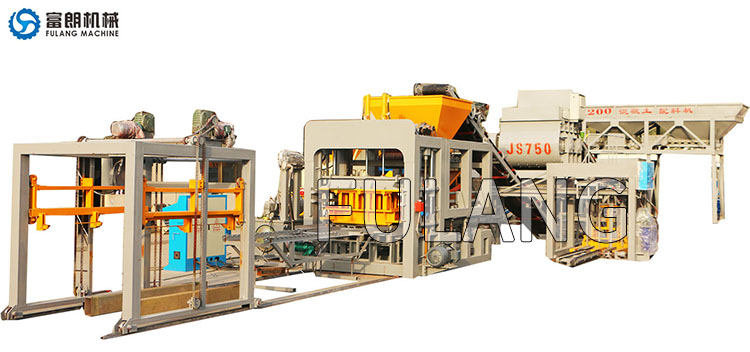

Now the automation degree has become higher. Almost all the middle size block making machine has been equipped with the production line accessories. For example, the stacker, the material mixer machine, the material convey belt, etc. Even the fork lift can be choose if you need. The automation has saved the labour force for most brick manufacturing factory. Further more, it improves the working efficiency, more profit can be made by the factory.