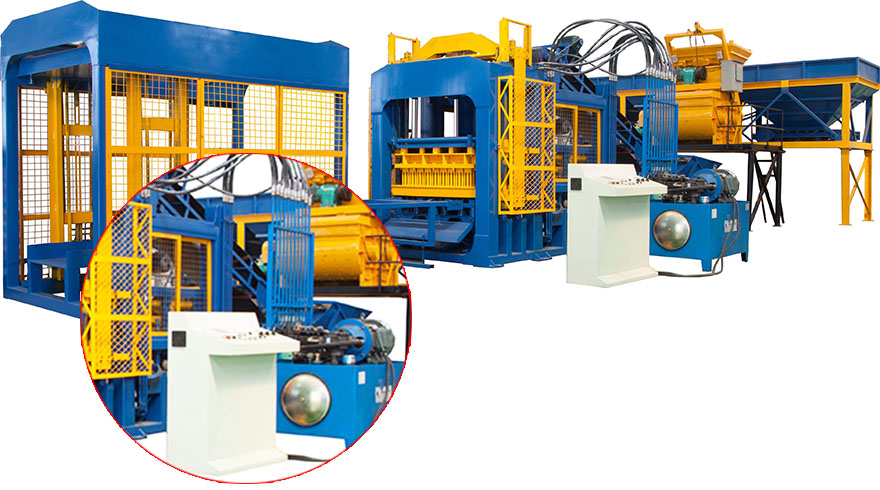

The automatic brick machine is mainly composed of six control systems: electrical control system, forming control system, feed control system, batching control system, and deceleration drive system.

And they must have the following core technologies:

♦ 1. The transmission part is fully sealed, the transmission part is fully sealed, automatic oil supply, circulation lubrication, no need to manually spray oil.

♦ 2. The rotating rod is separated from the gear body to completely seal the crankshaft gear pair.

♦ 3. The dosing mechanism uses worm drive to make the ingredients simpler and more reliable.

The molding system uses high-speed flywheel energy storage, low power, high pressure, and good brick formation. Eight equal parts of the brick cavity are arranged on the turntable, and the eight-hole disc rotates the one-way pressure machine. The turntable rotates counterclockwise intermittently along the neutral axis under the action of the eccentric pull rod.

♦ 4. Piston pump pressure oil supply, multiple dustproof, circulating lubrication, compact and reasonable structure, energy saving and high efficiency, novel and advanced, beautiful appearance, convenient operation and maintenance, safe and reliable.