Now, it has become a very common phenomenon to produce hollow block by using non burning brick machine. With the wide application of non burning block machine, more and more brick making machine manufacturers began to emerge. In the production, the basic process is the same, but there are many differences in details. For the layman, only look at the outside of the concrete block machine is not to see what difference. Only when we put it into production can we see the difference between machines. Therefore, we advise you to choose a high customer return rate and high praise manufacturers.

Today, let’s look at the four key points in the process of brick making machine production

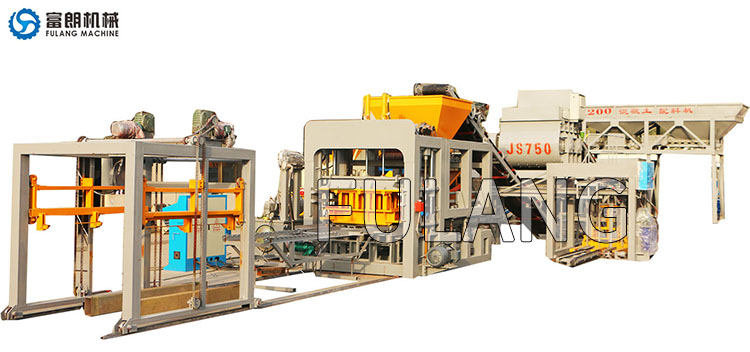

1. Each working link of hollow block making machine: feeding, mixing, molding, drying and other links should not only work well independently, but also coordinate with other connected links. Only in this way can the whole production line work smoothly, not only improve the production efficiency, but also extend the service life.

2. The second is the quality of hollow block mould. Good mold edge is smooth, not easy to stick material, not easy to burr, the hollow brick is relatively smooth, at the same time, the mold hardness is high, the use time is long, and the production cost is saved.

3. Molding pressure: make sure the molding pressure is large enough, which requires high production technology of hydraulic system or vibration system.

4. The structure of the brick machine is easy to maintain: in this way, customers can maintain the machine regularly in the process of use. In this way, the service life can be effectively improved. Sometimes many customers do not pay attention to regular maintenance in the process of use, resulting in the machine service life is not high, they will think it is the quality problem machine itself, in fact, there is no problem with the quality machine itself. Therefore, the manufacturer should consider how to improve the structure in the production process to make it more convenient for customers to maintain the machine regularly in the process of use.