Description

► Main advantage of this fully automatic block making machine

QTF10-15 is a high-end configuration of large-scale fully automatic unburned brick machine production line, it has the following main technical advantages:

- This machine realizes the integration of machine, electricity and liquid, PLC automatic control system, the whole process of monitoring each link, fault self-locking, fault detection and output statistics.

- Complete functions, advanced technology, suitable for the production of various types of concrete blocks, standard bricks, perforated bricks, road bricks, product quality, high pressure resistance, size accuracy and other advantages, in addition to the secondary distribution device can produce a variety of colored bricks, colored grass bricks and roadside bricks.

- Has a wide range of available raw materials: sand, stone chips, slag, gangue, coal ash, fly ash, slag and waste construction waste can be used as raw materials to produce bricks.

- High-end technology support in the world: It is equipped with Siemens motor, Mitsubishi control system, YUKEN hydraulic system, Schneider electronic control elements.

- High quality molds: using advanced wire cutting technology and carburizing heat treatment technology to create high-quality mold.

►Technical parameter

| Dimension of host machine | 3500*2300*2930mm |

| Weight of host machine | 9.8T |

| Power of host machine | 37KW |

| Vibration force | 100KN |

| Shaping period | 10-15s |

| Raw Materials | Crushed stone/Fly ash/Cement/Concrete |

| Products | Hollow,blocks,solid bricks,pavers,curbstones |

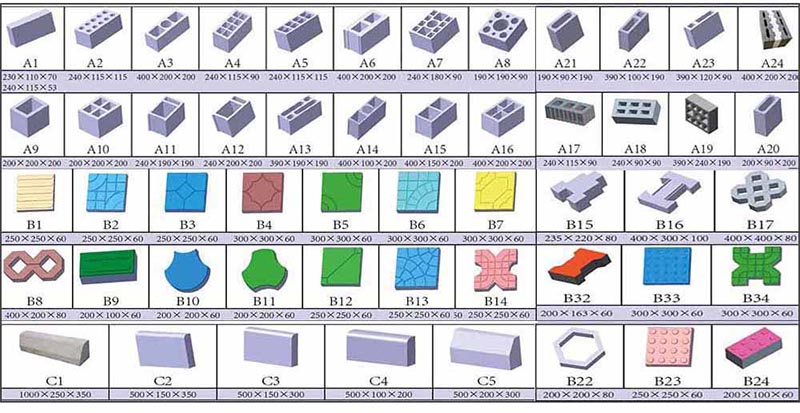

► Different shapes brick samples it can produce

These blocks are for reference only. If you have other requirements, we can customize them for you.

► Our production workshop