Description

QTF10-15F, QTF4-15F, QTF8-15F etc. fully automatic concrete insulation block making machine series can produce different kinds of insulated bricks, insulation blocks.

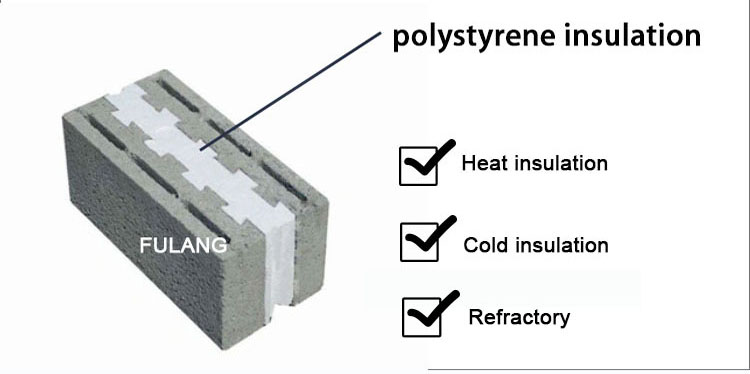

The inner and outer walls of the main block and between the main block and the outer protective layer are integrated by “L-type T-type point shaped connecting rib” and “point shaped column pin penetrating the insulation layer”, and steel wire is arranged in the column pin.

characteristic:

1. The heat preservation performance is good. Adjusting the thickness and density or variety of EPS board can meet the insulation requirements of buildings in different regions, different energy-saving stages and different shape coefficient buildings. The equivalent thermal conductivity of EPS composite self insulation block can be less than 0.15w / (m.k), which is difficult to be achieved by single material block. In this way, the wall thickness can be reduced, the weight of the building can be reduced, and the use area of the building can be increased accordingly.

2. Mechanized production, stable product quality. EPS composite self insulation block can be produced by using fixed block making machine, adding EPS mixing and tie bar placing measures and conveying device in the mold box. After pouring concrete mixture, it can be compounded and formed once by vibration pressure. After curing, the EPS board forms an integral whole with the concrete block and surface course, and the structure is firm, which can realize the integration of heat preservation and load-bearing, and has the same service life as the building.

3. The product is equipped with internal tie bars, wrapped in the concrete on both sides of the insulation layer, so the wall surface is not easy to fall off after being exposed to fire.

4. The surface has strong tensile and shear resistance. The tensile strength of the concrete surface layer increases exponentially by adding anti rust tie bar and adopting hot-dip galvanized low-carbon steel wire. The tensile strength of concrete surface layer reaches 150kn / m2, which is difficult for ordinary EPS external insulation wall.