Description

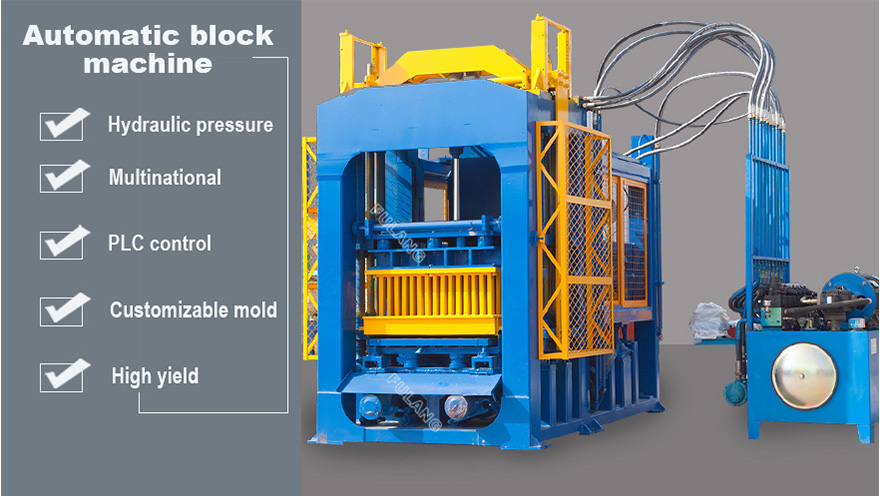

▶ Main advantage of this machine

- Multifunction: QTF6-15 automatic block forming machine can produce various blocks just by changing moulds, and the mould can be designed by us according to your requirement.

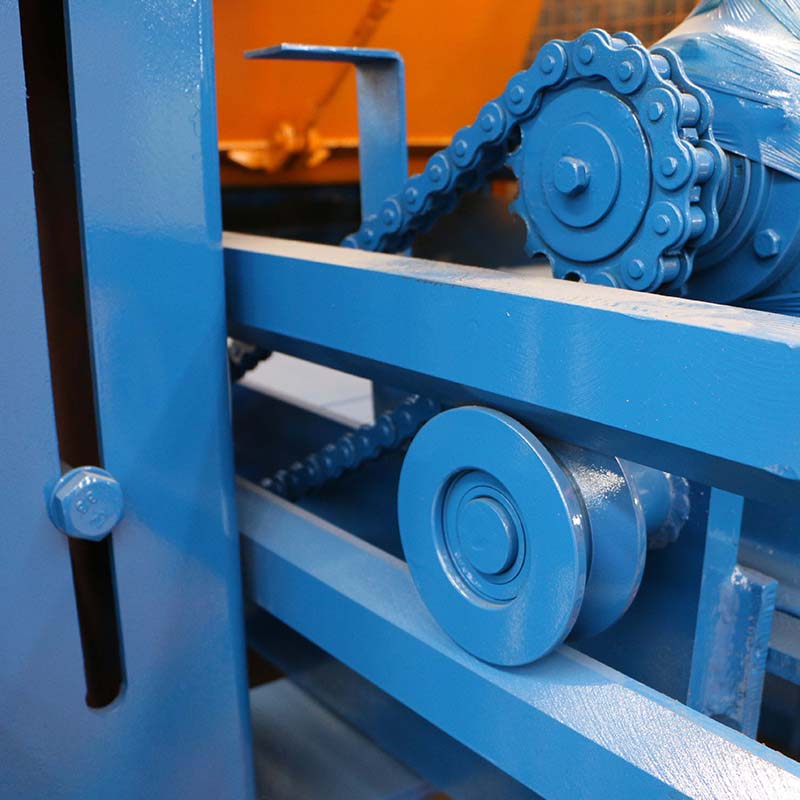

- Advance mould technology: In the production process of block mould, precision line cutting and carburizing treatment are adopted to prolong its service life.

- Advanced hydraulic technology: Hydraulic technology is adopted to ensure the blocks produced in good quality, high density and high strength.

- High level configuration: QTF6-15 is equipped with OMRON switch and SIEMENS motor. The original MITSUBISHI PLC control program is selected to ensure that theblock machineworks smoothly and efficiently.

▶ Technical Parameter and Production Capacity

| Technical Parameters | |||

| Dimension of host machine | 3500x1700x2930mm | Power | 29.1KW |

| Weight | 8.5T | Vibration force | 60-80KN |

| Molding area needed | 936x880mm | Mixer | JS750 |

| Water needing | 5-10T/Day | Block Pallet | 980x900x25mm |

| Theoretical Production Capacity | |||

| Size(LxWxH) | Pcs/Mould | Pcs/Hr | Pcs/8Hr |

| 400x100x200mm | 16 | 2880-3360 | 23040-26880 |

| 400x150x200mm | 10 | 1800-2100 | 14400-16800 |

| 400x200x200mm | 8 | 1440-1680 | 11520-13440 |

| 400x250x200mm | 6 | 1080-1260 | 8640-10080 |

| Solid:230x110x70mm | 33 | 5940-6930 | 47520-55440 |

| Paver:200x100x60xmm | 32 | 5760 | 46080 |

▶ Different shapes brick samples for your reference

The below brick shape is just for your reference, and we can design other brick mould according to your special requirement.

▶ Installation service abroad