Description

QT 4-15c fully automatic block/brick making machine production line

■ Introduction of this full automatic brick machine

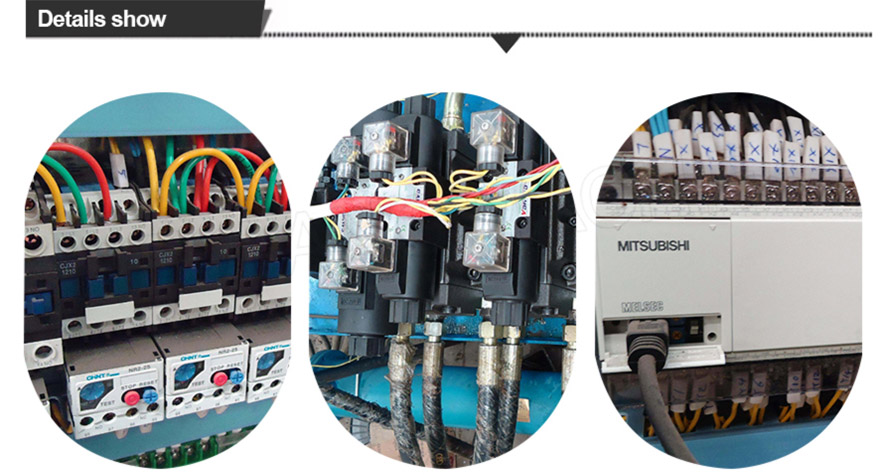

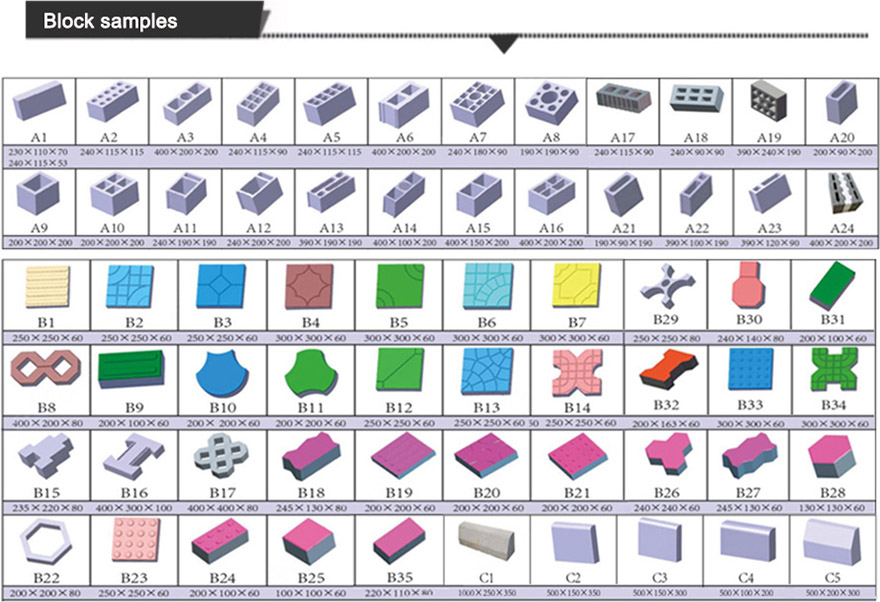

QT4-15 multi functional full automatic block machine, capable of making different specifications and forms of road paver, hollow brick, solid brick, curbstone. To achieve fully automatic production, this machine adopts computer PLC central control system, this could save lots of labor cost. Using four – bar – oriented method and ultra – long – oriented bearing, precise movement of the mould and press head could be guaranteed, which extends the service life of this block machine price. The body of QT4-15 are made of super steel, using special welding technology, but this machine price is not so high among the automatic block making machine market, which makes this machine a good investment. The products are of high strength, good compactness, the appearance size is accurate, and there is no shape rules or off angle. You can trust our machine price, we offer one year guarantee, and you can always call us for technique support.

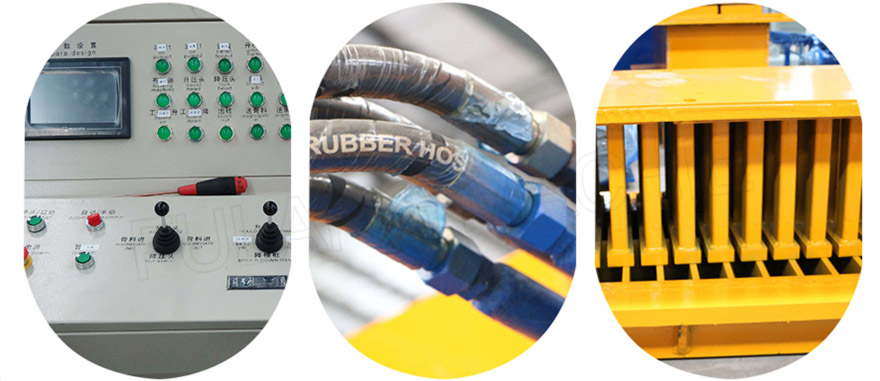

1. Advanced drive by wire technology and hydraulic conveyance system can assure you an easy operation and well performance.

2. QT4~15 China Famous brick machine will make more blocks than others you may get from other sources,which suit to you who need more solid blocks.

3. The speed of making blocks will be more higher.it has an easy operation with little error.

4. As for the quality of it, i must say that we use the steels of high quality,which was produced by JI steel making company known to all throughout China.,the quality of our machine is guaranteed.

5.The mold use the technology of carburization heat treatment ,which can give you a guarantee that there are will no transformation with 4 million blocks about 6-8 months.

6. It can produce different kinds of blocks with change of mold.

7. The materials can easily get and the source of material are wide enough to get.

8. Our product is value for money, high technology, high quality, high efficiency will give you a high return rate, so this kind of machine will be your best choice.

■ Main technical parameters

|

Theoretical Data |

||||||

| Dimension of host machine | 4000x1800x2800mm | |||||

| Main vibrator style | lower mould vibration | Number of hydraulic vibrator | 2 | |||

| Control style | PLC | Forming style | hydraulic | |||

| Number of motor vibrator | 2 | Hydraulic cylinders | 2 | |||

| Hopper capacity of concrete | 0.3 M3 | Feeding style | 360degree revolve | |||

| Moulding area | 1010×600 mm | Forming height | 40-250mm | |||

| Moulding period | 15-20 S | Vibration force | 40-50 kn | |||

| Forming blocks per mould400x200x200mm | 4 | The size of the pallet | 1010×550 mm | |||

| Weight of the host machine | 5T | Mixer style | JS500 | |||

| Water and Voltage | ||||||

| General water Consumption | 5-6 T | Voltage | 220v/380 V/420v/440v | |||

| Power | 21.7kw | |||||

| Simple line Used Area | ||||||

| A. Production area excluding concrete mixing zone | M2 | 300 | ||||

| B. Concrete mixing zone area | M2 | 170 | ||||

| B. Finished product Warehouse | M2 | 800 | ||||

| E. Raw material storage | M2 | 700 | ||||

| F. office | M2 | 100 | ||||

| G. Total area | M2 | 2070 | ||||

| Practical workers arrangement | ||||||

| Control/operation | 1 | Wheel loader | 1 | |||

| Forlift/pallet added | 2 | Repaire/maintain | 1 | |||

| Sum | 5 | |||||

| Production capacity | ||||||

| Size(LxWxH) | Pcs/Mould | Pcs/ Hr | Pcs/8 Hr | |||

| 400X100X200 | 8 | 1440-1680 | 11520-13440 | |||

| 400X150X200 | 6 | 1080-1260 | 8640-10080 | |||

| 400X200X200 | 4 | 780-840 | 5760-6720 | |||

■ Customer visiting

Till now,about 1200 customers have visited our factory.Also we have engineers staying abroad to help you install machines and training your workers at your side.

■ Engineers are available for installation abroad