Description

▶ Main advantage of this machine

- QT8-15 automatic fly ashbrick making machinefull line includes host machine section, batching section, and stacking section, capable of making hollow block,solid block, curbstone and color paver with color material feeding machine.

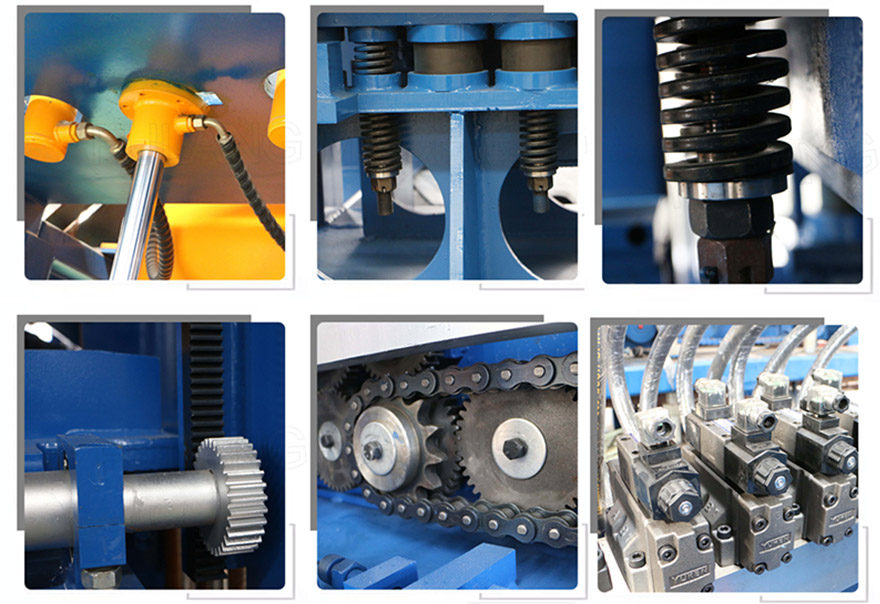

2. This concrete blocks making machine adopts PLC control and lots of sensor to achieve high accuracy.

3. With unique design of the material storage system, this concrete blocks making machine has high material feeding precision, so the products of this automatic cement block moulding machine are of high strength and intensity because it apply mould and table synchronous vibration plus high pressure at the same time.

3. And molding cycle is shortened by using high speed hydraulic cylinder, therefore production capacity is highly increased.

4. The guide pillar of this machine is made of super special steel, the surface has good anti – torsion and wear resistance. With automatic fault diagnosis system, remote monitoring and control, the trouble are easily detected and dissolved.

5. We sell lots of machines all around the world, definitely good choice to invest on this machine, and you will earn your money back in less than one year!

▶ Technical Parameter and Production Capacity

| Dimension of host machine | 3500x1700x2930mm | Power of host machine | 36kw |

| Moulding Period | 15~20s | Pallet size | 980x900x30mm |

| Vibration force | 80~90kn | Weight | 8.5t |

| Concrete mixer | JS750 | Products | Hollow block, solid block, paver, curbstone |

| Workshop | 300m2 | Raw material | Crushed stone, sand, cement, fly ash, cinder etc. |

▶ Installation service

▶ Packing and Delivery