Description

▶ Main advantages of QTF 4-15 fully automatic brick block making machine

- Multi-function: it can produce different shape of bricks by changing moulds to meet your different requirement.

- Super steel structure: ensure stability and reliability of main body, so this concreteblock machineare noted for their fine workmanship and durability

- PLC intelligent control was adopted in the whole process: easy to analyze opportunistic signals, ensure the best operation results.

- Efficient super strong vibration system and PLC controlled flow pressure of hydraulic system: ensure the quality of bricks produced.

- Realizing vertical synchronous vibration and Semi closed screen rotary feeding device: forced feeding at uniform and uniform speed to ensure product strength.

▶ Main technical parameter

| Dimension of host machine | 3800×1800×2550mm | Host machine power | 27 KW |

| Moulding area | 400×800mm | Vibration force | 40KN |

| Moulding period | 10-15S | Mixer model | JS500 |

| The size of the pallet | 1010×550×20/25mm | General water Consumption | 4T/every day |

| Weight of the host machine | 5.1T | Voltage | adjustable |

▶ Production capacity samples

| Model |

Size/mm |

Each plate number of brick |

Block / hour |

Block /8hours |

| Hollow block |

390x190x190 |

4 |

600 |

6000 |

| Standard brick |

240x115x53 |

28 |

3600 |

36000 |

| Paver block |

200x163x60 |

8 |

1440 |

11520 |

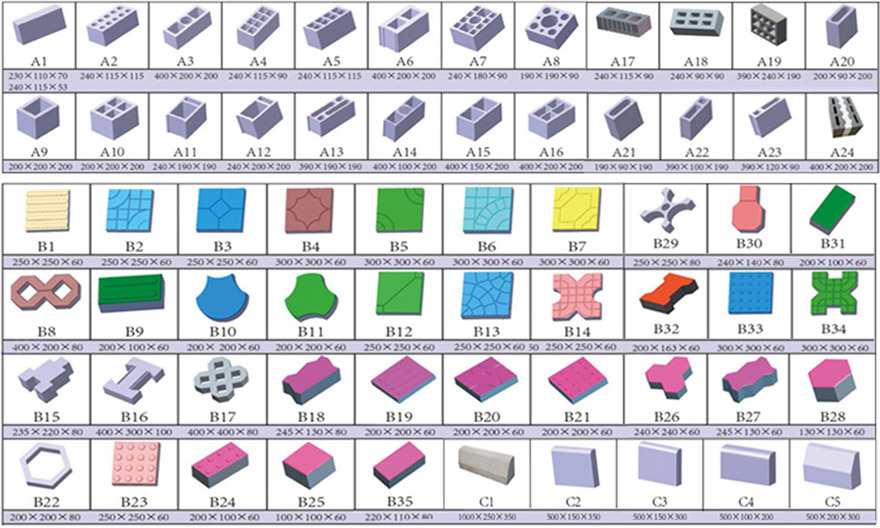

▶ Brick shape samples

▶ Our company