At present, the problems faced by China’s building materials industry.

At present, housing consumption has become the dominant consumption of the majority of the people, and the building materials industry closely related to real estate has undoubtedly become the beneficiary. However, a series of problems that followed have gradually emerged. The production of building materials in various places has led to the occupation of large arable land and the serious pollution of the air.

The solution adopted by the Chinese government.

Accordingly, our government has set up a special agency to force the elimination of burning solid clay bricks throughout the country, and at the same time to reduce taxes, support and other preferential policies for enterprises that adopt new technologies, new materials, new equipment, new processes, energy conservation and product protection. The new environmentally-friendly recycled building materials have received national key support for their energy saving, pollution-free, industrial waste consumption and superior performance. A huge market, low investment, free raw materials, and national preferential policies are good projects for investment.

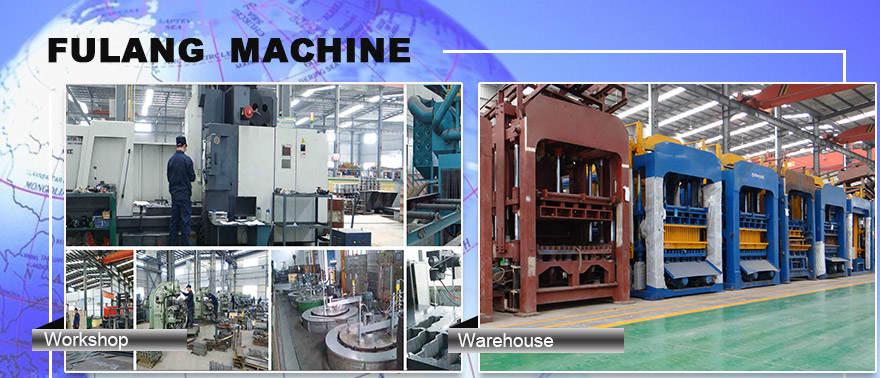

FULANG MAHCINE plays it’s huge role.

FULANG MAHCINE has a comprehensive research and development base integrating scientific research, production and training. With its high-tech talents, advanced technology and equipment, and perfect operation mechanism, it has developed a series of environmentally-friendly and energy-saving equipment and products. The burning-free

brick machinery is the most important project of research and development of FULANG MACHINE. We provide different kinds of manual and fully fully automatic fly ash

brick machine, egg laying concrete

block making machine and many others

brick equipment.

The great advantage of non-burning brick machine.

The non-burning

brick machine has a high quality advantage. It can be used for the production of

hollow blocks, perforated bricks, interlocking bricks and any models you need just by changing the mold. It has high automation and PC program automatic and Manual control of dual functions; cutting, forming, and exporting are completed continuously, safe and stable operation, easy to maintain; high cost performance and high output. The non-burning brick produced by the non-burning block equipment, like hydraform

brick making machine for sale, its characteristics are not found in any other wall bricks, using fly ash, slag and other waste slag as raw materials, with a reasonable scientific formula, according to a certain proportion of the equipment process Strengthening the treatment to achieve the plastic state, the utility of the brick is good, the wall is not immersed, and the appearance is neat, for example, the

concrete hollow block making process and cement bricks manufacturing process. The raw materials for non-burning bricks are common and the production cost is low. This initiative is encouraged and supported by the state organs. It not only has significant economic benefits but also protects the environment. It does not need to seize the cultivated land, protect the cultivated land, avoid destroying the field; it does not need to be burned, which saves energy; the use of waste residue as raw material is conducive to environmental pollution. Because of its simple manufacturing process, low cost and fast environmental protection, it has won recognition from the international community and widely praised by users.